- Home

- Capability

- Products

- About Us

- Service Industry

- Service Cases

- Video

- Contact Us

-

Language

Language

Language

- CNC Programming: The cutting path is programmed into the CNC machine based on the CAD design. This involves defining the cutting lines and any intricate details that need to be cut out from the formed plastic.

- Fixture Setup: The formed plastic part is secured on the CNC machine using fixtures or clamps to ensure it remains stationary during the cutting process.

- Precision Cutting: The CNC machine, equipped with appropriate cutting tools (such as routers or end mills), performs precise cuts along the programmed paths. This step may include trimming excess material, cutting holes, or creating slots as specified in the design.

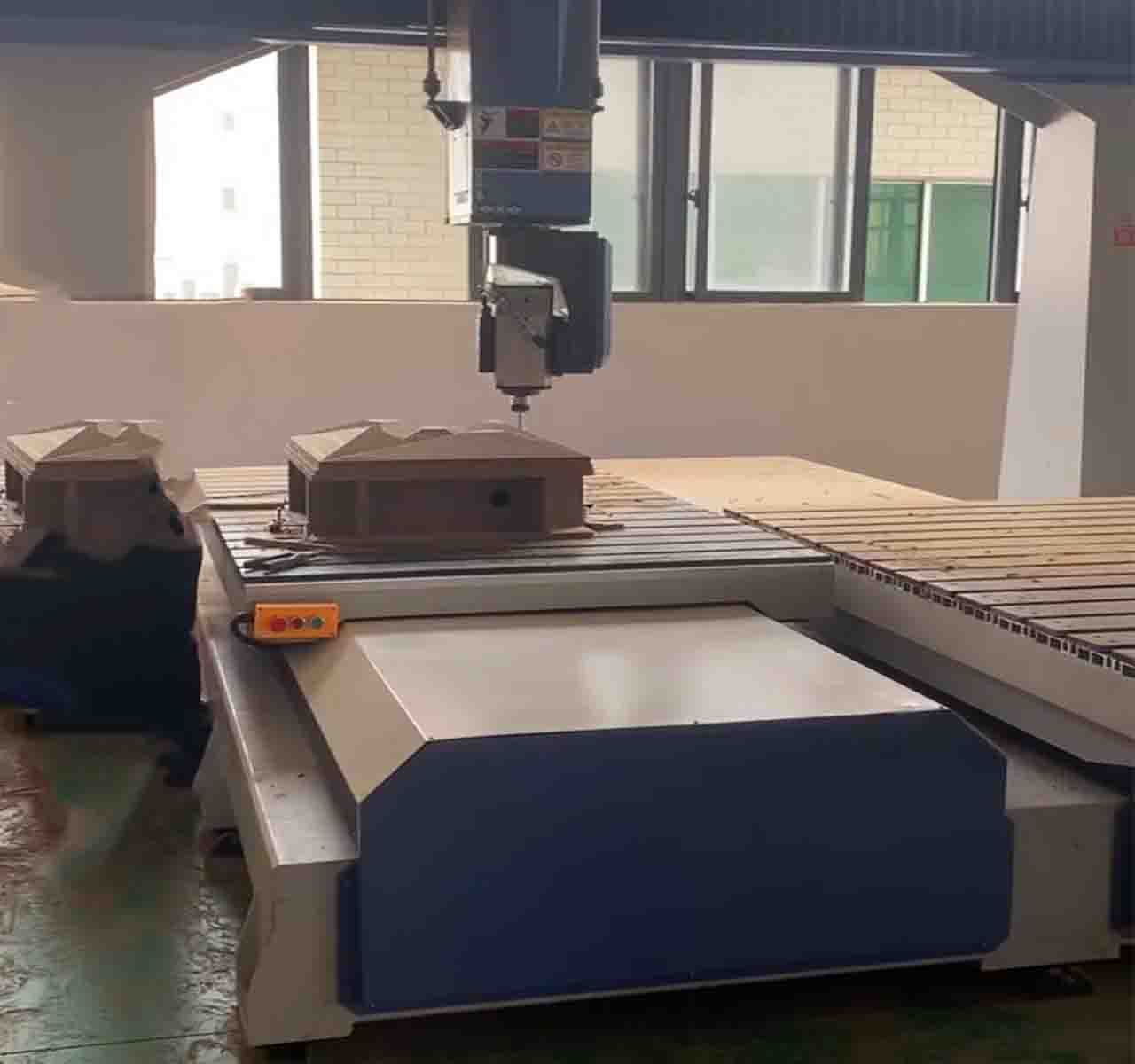

We have 4set of 5-Axis and 3 set of 3-Axis,

5-Axis can process 360 degrees of drilling, it can process complex shapes in a single pass, so we can achieve precise dimensions and save lots of time and cost.

Compared with 5-axis CNC have 360 degrees high speed for cutting products with more angles and curved surfaces, 3-axis CNC for cutting flat or simple curved surfaces.

3-Aix CNC Cutting Machine 5-Axis CNC Cutting Machine