- Home

- Capability

- Products

- About Us

- Service Industry

- Service Cases

- Video

- Contact Us

-

Language

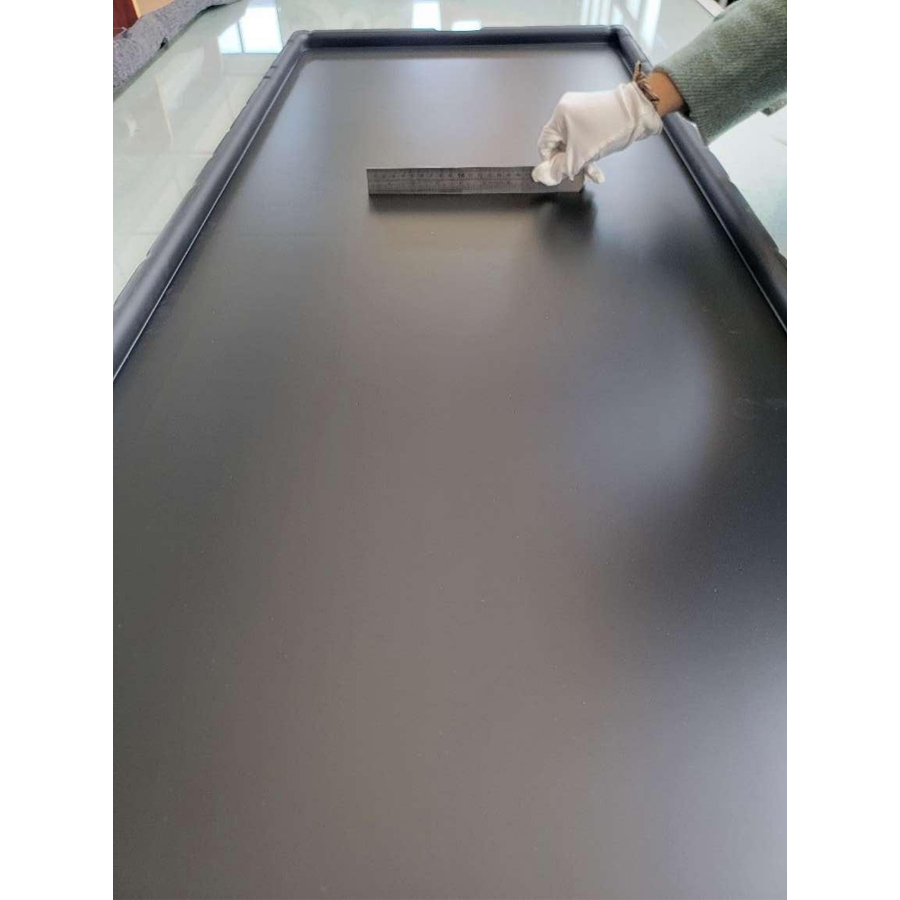

A company that manufactures anti-static trays contacted us in April 2024 to custom-make trays for them. However, due to a price difference with their existing supplier, they initially chose not to proceed with us. In November, the customer reached out again and requested a sample. During our discussion, the customer mentioned that their current supplier’s trays had the following issues: 1. Slight deformation due to the elongated design; 2. Surface imperfections such as particles, crystallization points, and scratches; 3. Uneven surface. The customer asked if we could resolve these problems. Based on our stringent material requirements and the affirmation from our experienced technicians, we confirmed that we could address these issues. The next day, the customer brought a mold sample to us. After sampling and confirmation, the customer approved the sample and placed an order for production. Subsequently, they also entrusted us with several other tray designs. During production, the customer sent a team to conduct full inspections, measuring the glass surface with a level. The final product passed with a 99.5% success rate.