- Home

- Capability

- Products

- About Us

- Service Industry

- Service Cases

- Video

- Contact Us

-

Language

Language

Language

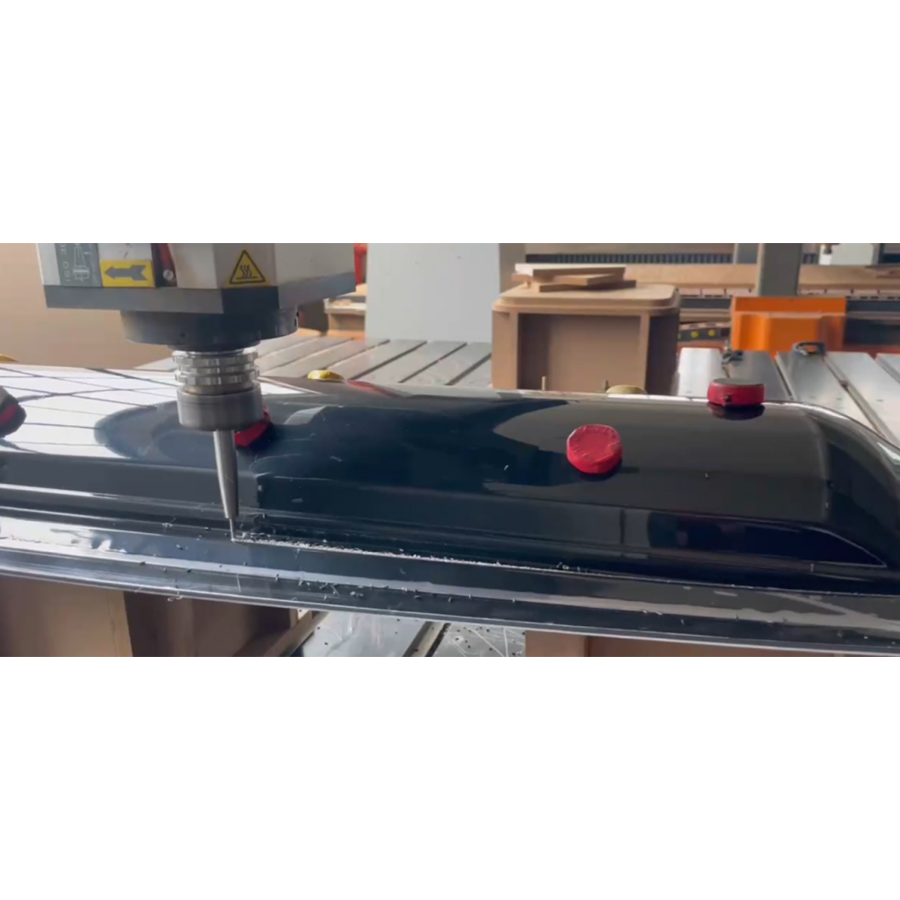

A customer specializing in automotive outdoor accessories contacted us to customize a sunshade box for the car roof, with dimensions of 1288*200mm. The wall width of the upper and lower shells needed to be controlled within ±3mm, and the wall thickness also required a tolerance of ±3mm. Any dimensional discrepancies would cause gaps between the upper and lower shells, leading to issues with the assembly of other components and injection-molded parts. Moreover, water could seep into the box, potentially damaging the internal motor. The customer had previously worked with another factory, but frequent errors led to rework or modifications to the parts. Given the elongated shape of the shell, slight deformation during production could cause uneven edges. Through the expertise and adjustments of our engineers with 20 years of experience, we successfully ensured uniform wall thickness and straight edges, making the assembly process much smoother for the customer.