- Home

- Capability

- Products

- About Us

- Service Industry

- Service Cases

- Video

- Contact Us

-

Language

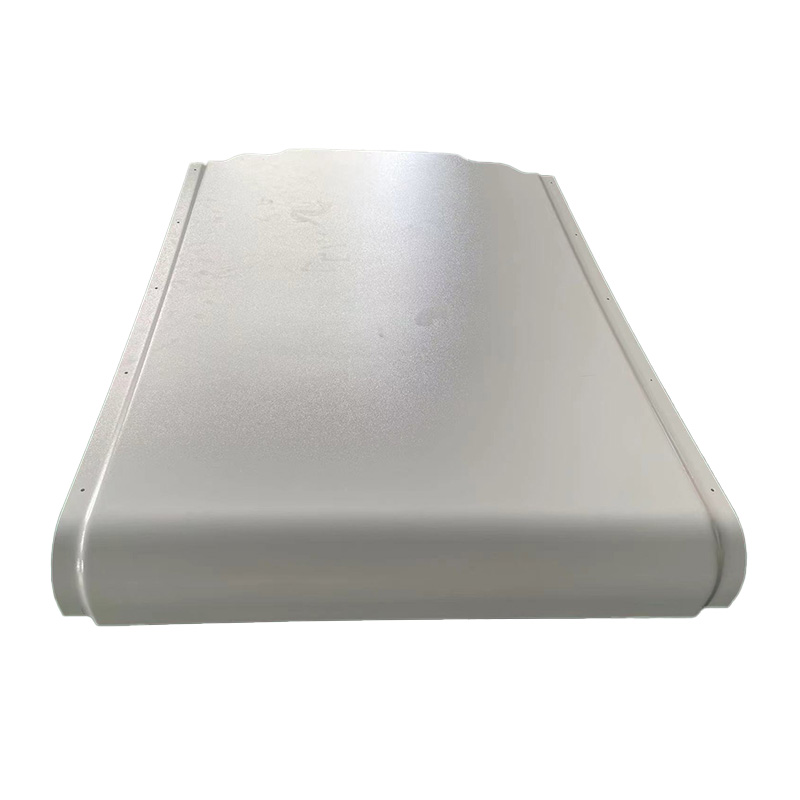

Thick sucking and plastic processing is used to manufacture machine equipment shells, which has the advantages of high strength, durability and lightweight. This process uses thermoplastic plastic sheet and forms on the mold to achieve a shell of accurate matching equipment structure. A variety of materials such as ABS and polycarbonate can be used to meet different performance needs. Its customized characteristics allow the design color, surface treatment and logo according to customer requirements to enhance the market competitiveness of the product and provide excellent protection functions.

Thick sucking and plastic processing is used to manufacture machine equipment shells, which has the advantages of high strength, durability and lightweight. This process uses thermoplastic plastic sheet and forms on the mold to achieve a shell of accurate matching equipment structure. A variety of materials such as ABS and polycarbonate can be used to meet different performance needs. Its customized characteristics allow the design color, surface treatment and logo according to customer requirements to enhance the market competitiveness of the product and provide excellent protection functions.

Machine and equipment shell for thick -sucking and plastic processing

Thick suction and plastic processing is an efficient manufacturing process, which is widely used in the production of machine -equipment shells. This process involves heating the thermoplastic sheet to soften, and then forms it on the mold through vacuum or pressure to obtain a shell for the required shape and size. This process has the following advantages:

Excellent durability: Thick -suction shell has good impact resistance and abrasion resistance, and can effectively protect the internal components from being influenced by the external environment.

Accurate size and shape: By using precision molds, thick -absorbing processing can achieve high -precision shell molding to ensure the perfect fit with the internal structure of the machine.

Various materials selection: You can choose different types of plastic materials according to different application requirements, such as ABS, polycarbonate or polypropylene to meet different performance requirements.

Lightweight design: The shell of thick and plastic processing is relatively light, which helps reduce the overall weight of the equipment and improve the convenience of transportation and installation.

Customized ability: According to the specific needs of customers, the color, surface processing and printing patterns of the shell can be customized to enhance the market competitiveness of the product.

Application

Industrial equipment: used to protect manufacturing equipment, production line controllers, etc.

Medical equipment: Provide light and durable shells for medical instruments.

Automatic vending machine: Provide a solid and beautiful external coverage.

Automotive industry: used for internal and external decoration.

Electronic equipment: Provide customized cases for large electronic instruments and equipment.

Logistics transportation: Protect transportation equipment and reduce the overall weight.

Excellent durability: Thick -suction shell has good impact resistance and abrasion resistance, and can effectively protect the internal components from being influenced by the external environment.

Accurate size and shape: By using precision molds, thick -absorbing processing can achieve high -precision shell molding to ensure the perfect fit with the internal structure of the machine.

Various materials selection: You can choose different types of plastic materials according to different application requirements, such as ABS, polycarbonate or polypropylene to meet different performance requirements.

Lightweight design: The shell of thick and plastic processing is relatively light, which helps reduce the overall weight of the equipment and improve the convenience of transportation and installation.

Customized ability: According to the specific needs of customers, the color, surface processing and printing patterns of the shell can be customized to enhance the market competitiveness of the product.