- Home

- Capability

- Products

- About Us

- Service Industry

- Service Cases

- Video

- Contact Us

-

Language

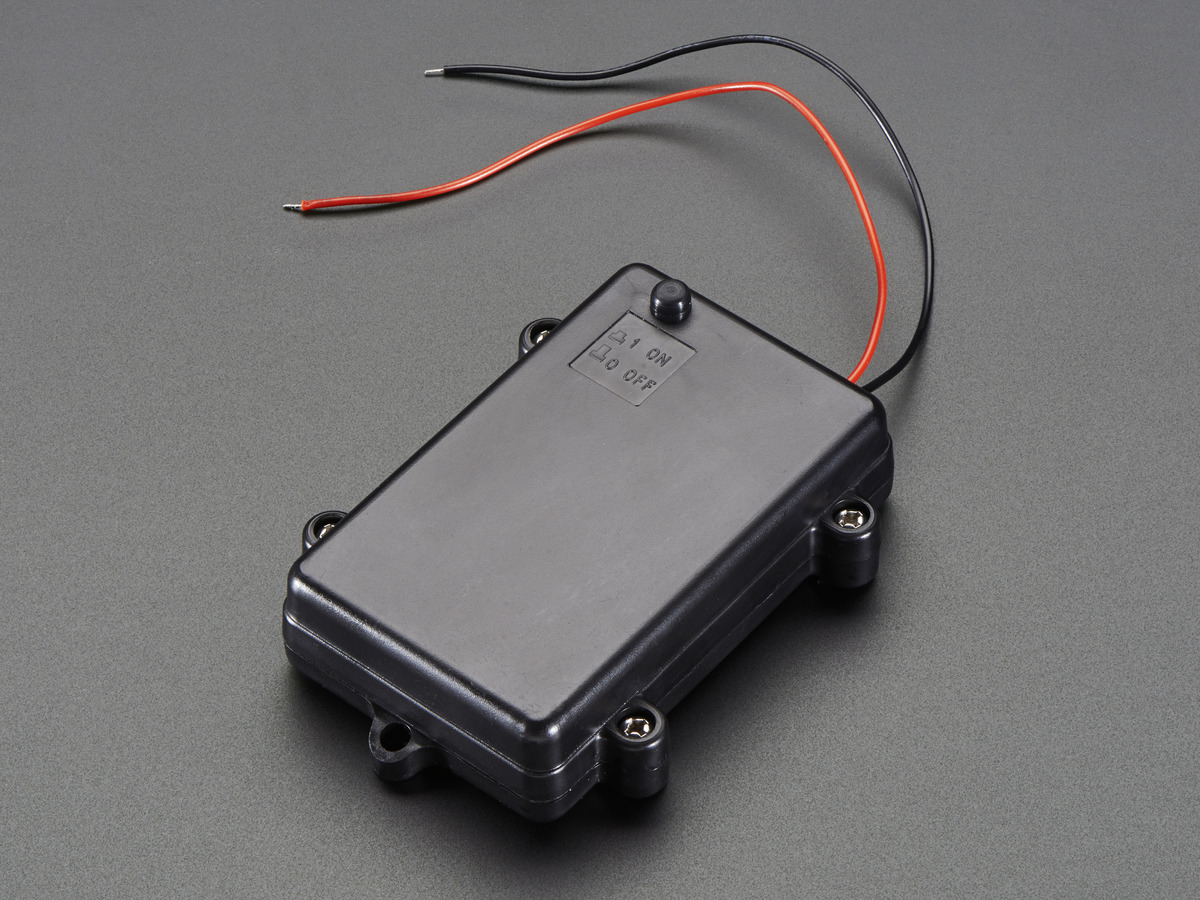

Thermoformed battery enclosures are protective casings designed to house and safeguard battery packs. These enclosures are created using thermoforming, a manufacturing process that involves heating a thermoplastic sheet to a pliable forming temperature, shaping it in a mold, and then cooling it to maintain the desired shape. This process provides a high degree of precision and customization for battery enclosures.

Advantages

1. Customizable Design

Tailored Fit: Thermoforming allows for precise customization of the battery enclosure’s shape and size, ensuring a perfect fit for various battery packs.

Complex Shapes: Capable of producing intricate geometries and functional features such as ventilation holes, cooling fins, and mounting brackets to meet specific application needs.

2. High Durability

Impact Resistance: Materials like ABS and polycarbonate used in thermoforming offer excellent impact resistance, effectively protecting the battery from physical shocks.

Environmental Protection: Provides robust protection against dust, moisture, and chemicals, thereby extending the battery's lifespan.

3. Superior Heat Dissipation

Cooling Design: Enclosures can be designed with ventilation openings or cooling fins to facilitate effective heat dissipation, preventing overheating and enhancing battery performance and safety.

4. Cost-Effectiveness

Economical Production: Thermoforming is generally more cost-effective compared to other molding processes like injection molding, particularly for low to medium production volumes.

Rapid Turnaround: Enables fast prototyping and production, accelerating the time-to-market for new products.

5. Material Versatility

Material Options: Various thermoplastic materials, such as ABS, PETG, and TPE, can be used, each offering different mechanical properties and chemical resistances to suit diverse applications.

6. Lightweight and Easy Handling

Lightweight Design: Thermoformed enclosures are typically lighter than those made from other materials, making handling and installation easier.

Simple Maintenance: Designed for easy access to battery components, simplifying maintenance and replacement.

7. High Production Flexibility

Small-Batch Production: Ideal for small-batch production needs, allowing for quick design changes and adjustments to production specifications.

Fast Response: Rapidly responds to market demands and design modifications, reducing development time.

8. Certifications and Compliance

Industry Standards: Enclosures can be manufactured to meet various industry standards such as UL (Underwriters Laboratories) for electrical safety and IP (Ingress Protection) ratings, ensuring product safety and reliability.