- Home

- Capability

- Products

- About Us

- Service Industry

- Service Cases

- Video

- Contact Us

-

Language

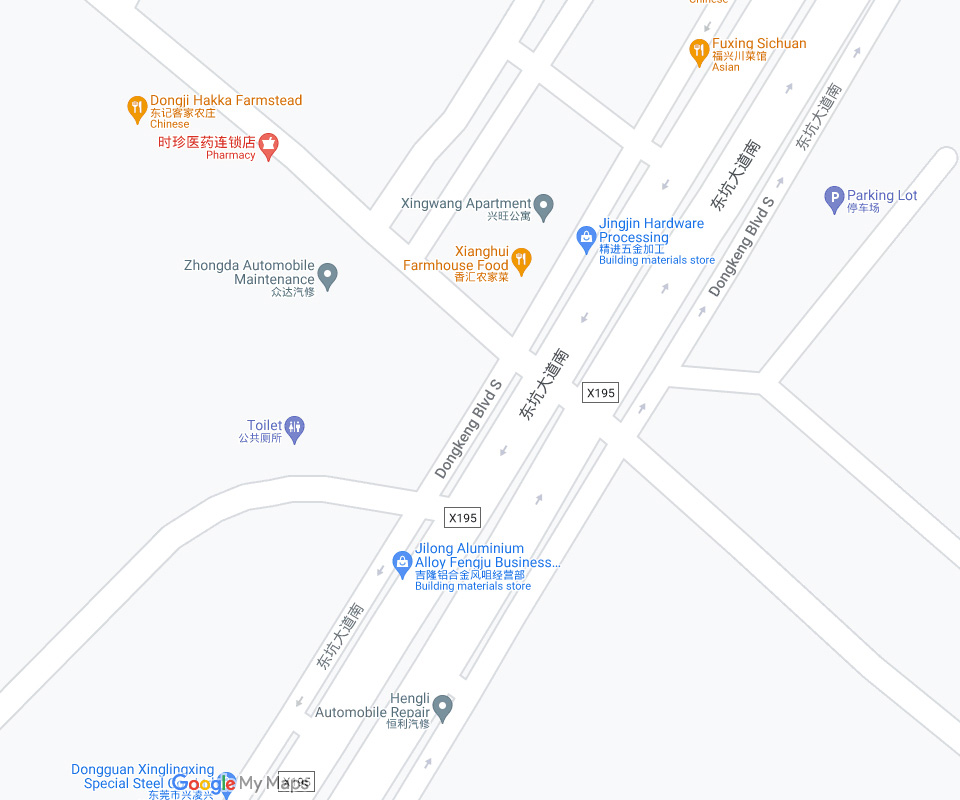

Dongguan lucky vacuum forming Co., Ltd. is a leading manufacturer specializing in custom-engineered vacuum-formed plastic products, mold design, and sales. Located in Dongkeng Town, Dongguan City, China, our company spans 5000 square meters and boasts over a decade of experience with a skilled team and comprehensive equipment lineup.

Custom Vacuum Forming Expertise: We excel in producing a wide range of large, thick vacuum-formed plastic products, including robot shells, medical equipment casings, pallets, automotive body parts, luggage compartments, lampshades, sports equipment, toy vehicles, drone enclosures, E-sporting gear, charging stations, hospital bed boards, display racks, and more.

Our products cater to various industries such as automotive, medical, household appliances, artificial intelligence, and electronic instruments, meeting the unique needs of different sectors.

Automobile Transportation Industry

Other Plastic Products Industry

Medical Device Industry

Household Goods Industry

Electronics Industry

Furniture Industry

Food Industry

Home Appliance Industry

Our skilled technicians and engineers have over 20 years of industry experience, enabling us to tackle complex technical challenges and deliver professional solutions to our clients.

With 15 years of experience in international trade, our foreign trade manager can communicate thoroughly and effectively in English Via email and orally.She know much about vacuum forming process and all foreign trade process,giving customers good plastic solutions.

Send you project and communicate with her now! janet@luckyvacuumforming.com

A seasoned professional with over a decade of experience in vacuum forming has achieved notable success in the field. Possessing deep expertise in vacuum forming processes, they can design and optimize vacuum forming molds, ensuring efficient production operations. Through extensive research on various plastic materials, they can select the most suitable materials for project requirements, thereby enhancing the quality of the final products. Within the team, they demonstrate outstanding leadership and communication skills, driving the smooth implementation of projects. This vacuum forming engineer not only has a mastery of industry standards but also possesses keen insights into emerging technologies, making outstanding contributions to the company's innovation and development.

With twenty years of manual model making experience in the vacuum forming industry, this professional has amassed a wealth of expertise through years of accumulation and refinement. Proficient in various manual model making techniques and processes, they are capable of producing hand models of various complex shapes.

Having been responsible for the production of various large-scale exhibition hand models, they can independently handle all processes from design blueprints to manual production, finishing, and polishing, ensuring customer satisfaction.

With over twenty years of experience in vacuum forming machine operation, this individual boasts a wealth of expertise and proficiency in operating and maintaining various types of vacuum forming machinery. They possess deep knowledge of plastic materials, enabling them to adjust machine parameters according to different requirements, produce various complex vacuum-formed products, and ensure smooth production processes.

Throughout their extensive career, they have accumulated rich experience in troubleshooting, allowing them to quickly and accurately address any issues that may arise with vacuum forming machines. This master craftsman prioritizes teamwork and excels in guiding novice employees, providing reliable technical support for the company's vacuum forming production.

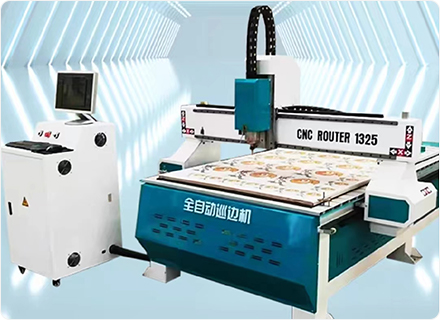

With over twenty years of experience, the CNC master craftsman is highly skilled, proficient in operating and programming various types of CNC machine tools. They possess deep knowledge of metal processing and cutting techniques, efficiently utilizing 5-axis machining technology for precision manufacturing.

Having accumulated extensive experience in machining over many years, they excel at adjusting machine parameters based on design blueprints and requirements, ensuring that product quality meets the highest standards. This CNC master values precision and efficiency, remains sensitive to new technologies, continuously updates their knowledge, and provides reliable manufacturing technical support for the company.

We offer a one-stop solution from mold design, manufacturing, vacuum forming, CNC machining, to complex assembly production, ensuring our customers receive customized, high-quality finished products.

Adhering to ISO quality management standards, we implement rigorous quality control measures throughout the production process, guaranteeing the excellence of our products.

Engineering and R&D

Mould Manufacturing.

Sample Drawing Discussion

Plastic Sheet Production

Thick Film Blister Processing

5-Axis and 3-axis CNC Machining

Assembly of Handmade Boards

Silkscreen

Oil-Spraying

Galvanise1

Quality Inspection

Packaging for Shipment

CNC for cutting flat or simple curved surfaces.

Tooling machine,make the mold that we need.

Can process 360 degrees of drilling, it can process complex shapes in a single pass

The Max size can do is :3000mmx2000mm

The thickness can do :1mm-16mm

The material can vacuum forming:ABS, HIPS, PMMA, PVC, PC, PETG, PP, PE, ASA, ABS+PMMA, ABS+PC

The Max size can do is :2000mmx1600MM

The thickness can do :1mm-16mm

The material can vacuum forming:ABS, HIPS, PMMA, PVC, PC, PETG, PP, PE, ASA, ABS+PMMA, ABS+PC

Make all kind of small molds

At Dongguan lucky vacuum forming Co., Ltd., we are committed to providing innovative, high-quality plastic solutions tailored to our customers' needs. With state-of-the-art manufacturing equipment, refined processing techniques, superior product quality, and excellent after-sales service, we strive to be your trusted partner in custom vacuum forming, mold design, manufacturing, and assembly.